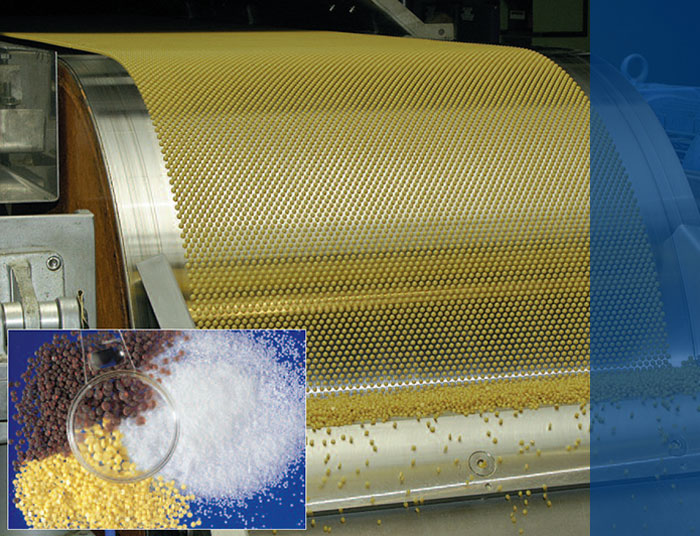

Required methods and equipment for transforming liquid into solid particles:

Transformation of a liquid to solid particles (flakes – granule – powder – …) will happen in one of the following situations:

- The liquid is in fact the molten form of the product. Therefore, heat absorption and formation processes are sufficient to obtain the desired product. In this case, a drum flaker is used to obtain the product in the form of flakes (crushed flakes) or a granulator to have it in the form of granules (lens-shaped). The melt can also be formed with regular shapes (coin, star, etc.) by means of “molding machines.”

- The liquid is in fact a homogeneous solution consisting of a base solvent and the product. In this case, one of the following methods could be used:

- Concentration of the solution to a suitable extent and solidification in another machine. (For more inform. see the “products/concentrators” page).

- Simultaneous concentration and solidification are in one machine. This can be done using a spray dryer (to obtain soft powder) or fluidized bed tower (to achieve small spherical particles). In both cases, the solvent is vaporized by hot air flow.

- The liquid is in fact a homogeneous or heterogeneous mixture of a liquid and suspended solid particles. For example, a mineral slurry whose solid particles are separated from the water by a filter press.

Customer feedback

We are proud that most of the ads are done by previous customers.