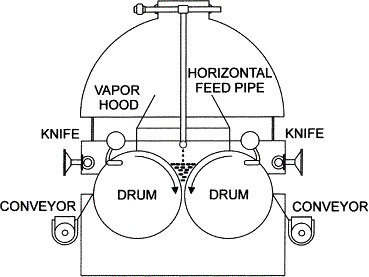

Drum Dryer is used to transform a concentrated solution into solid particles (granules or flakes).

Continuous streams of hot water or hot oil, or a wide (decentralized) flame is used inside the drum to heat the fed solution.

A Hot Drum often consists of the following: Hot Drum, Feeder, Cutter, Drive, Chassis, Cover, Auxiliary Mechanisms, and Electric and Control Panels. This machine is structurally very similar to Top Feeder Flaker, except that a hot fluid is sprayed inside the drum to provide the necessary heat for evaporating the solvent or cooking the material.

The material of the drum is selected considering the type of the solution (taking into account corrosion and guild standards), while its size is selected based on the capacity of the machine. Where the drum surface is to be very heated (more than 250 ° C), a wide distribution heater (electric or gas) is installed inside the drum. The concentrated solution is usually poured on top of the drum and spread out by a small roller. The thickness of the film is controlled by changing the gap between the roller and the drum surface. Similar to a flaker, this machine has mechanical and thermal load values, which should match in order for the solid material to be sufficiently dry at the moment of removal. If the solid is formed granularly due to the nature of the product, then a separating brush will be used instead of the scraper blade. In cases where the solvent vapors are toxic, flammable, or vexing, the machine would be separated from the workshop space by means of a cover and the vapors would be directed out of the chimney or into the vapor evacuator. This machine is a cheap alternative to a spray dryer for solutions with sufficient levels of concentration.

Where the solid product is sensitive to temperature (the temperature required for complete drying of the product is higher than the tolerable temperature for the solid product), evaporation process is facilitated by installing a completely sealed cover and creating vacuum.